What Would You Put in a Supply Chain Time Capsule to be Opened in 2050?

From a toy forklift to a conveyor belt to paper documents, here are the relics from 2025 that our readers say will amuse and surprise supply chain professionals in 2050.

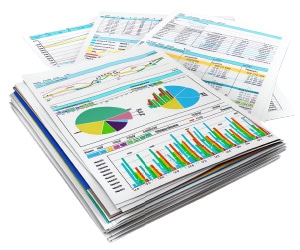

Burying Spreadsheets

Today’s spreadsheets, emails, and manual processes. By 2050, supply chains will be fully intelligent, automated, and collaborative, powered by AI and real-time data. Today’s tools will seem as outdated as the fax machine.

Today’s spreadsheets, emails, and manual processes. By 2050, supply chains will be fully intelligent, automated, and collaborative, powered by AI and real-time data. Today’s tools will seem as outdated as the fax machine.

–Rodney Manzo

Founder and CEO

Anvyl

I would put emails and spreadsheets in the time capsule, representing symbols of the inefficient, manual tools we once relied on to manage supply chains. By 2050, we’ll see them as relics of a past where data flow and collaboration were more challenging.

–Mark Buman

Chief Revenue Officer

Magaya

I would include an early 2020s spreadsheet-based sourcing plan. It will showcase our transition from siloed tools to interconnected, AI-powered platforms that ensure transparency, sustainability, and agility across global supply chains.

–Lilian Bories

CMO

TradeBeyond

A toy forklift with a little warehouse person action figure driving it, a desktop computer, a keyboard and mouse, and RF scan gun. It would be fun to see how much of it is being used in 2050.

A toy forklift with a little warehouse person action figure driving it, a desktop computer, a keyboard and mouse, and RF scan gun. It would be fun to see how much of it is being used in 2050.

–Bradley Mousa

Operations Manager

TA Services

A driver’s license to symbolize the human element in delivery. While technology and automation continue to advance, it’s a reminder drivers have been at the heart of supply chain success.

–Dennis Moon

COO

Roadie

A digital twin of our supply chain network, a container tracking device, a photograph of manual inventory ledgers, current AI in logistics, and a handwritten letter reflecting on the transition from carbon-intensive to sustainable logistics.

–Sam Agyemang

VP, Business Development and Sales

ITF Group

A 200-foot-long loop of belt-driven conveyor, a tunnel of line scanners, a push-arm divert, a human-driven fork truck, and a stand-alone warehouse management system. Put another way, what will the people of 2050 look back at and laugh?

A 200-foot-long loop of belt-driven conveyor, a tunnel of line scanners, a push-arm divert, a human-driven fork truck, and a stand-alone warehouse management system. Put another way, what will the people of 2050 look back at and laugh?

–Sandy Stephens

Chief Strategy Officer,

HyTek Intralogistics LLC

The 2024 map of major risk events and their blast radius to remind future generations that 2024 marked an inflection point for risk management. Hurricanes caused $50 billion in damages, Hezbollah device attacks reshaped modern warfare, and new ethical labor and sustainability regulations transformed corporate compliance.

–Ted Krantz

CEO

Interos

Our roadmap to net zero. Decarbonizing the supply chain will be a huge issue to future generations. By 2050, I hope we can say, ‘We figured it out.’

–Bob Boyle

President, Managed Services Division

Odyssey Logistics

Paper shipping and return labels. With artificial intelligence and machine learning, ecommerce will grow more advanced. By 2050, automation could eliminate the need for paper labels and manual parcel sorting.

Paper shipping and return labels. With artificial intelligence and machine learning, ecommerce will grow more advanced. By 2050, automation could eliminate the need for paper labels and manual parcel sorting.

–Kapil Kalokhe

VP, Corporate Development and Strategy

ePost Global

A 3-minute video of our warehouse operations and predictions for 2050 from 50 of our employees to educate, amuse, and provide valuable insights into today’s supply chain practices.

–Troy Strawhecker

Chief Strategy Officer & Partner

JT Logistics

A digital thread blueprint capturing how product lifecycle data integrates across systems—a snapshot of today’s advancements toward end-to-end traceability.

–Jason Kasper

Senior Director,

Product Marketing

Aras

Gloves. Often worn to protect workers from the strain and physical wear caused by manual repetitive tasks in warehouses, they may no longer be necessary in 2050.

Gloves. Often worn to protect workers from the strain and physical wear caused by manual repetitive tasks in warehouses, they may no longer be necessary in 2050.

–Joseph Ruck

VP, Marketing & Communications

Ambi Robotics

A flash drive with AI code would be proof of how we used data and algorithms to solve today’s supply chain challenges—and a glimpse into how far we’ve come.

–Christopher Clemmensen

EVP, Marketing

Echo Global Logistics

Biodegradable packaging, lifecycle maps, and upcycled goods to show circularity efforts. Blockchain ledgers, IoT sensors, and QR tools would highlight traceability, while certifications, sustainability reports, and policies reflect compliance.

–Wesley Ekman

VP EMEA

CGS BlueCherry

A desktop computer, like the ones many CEOs still keep under their desks. Managing supply chains with on-premise software is becoming impossible in the age of AI, where connectivity and access to data are everything.

A desktop computer, like the ones many CEOs still keep under their desks. Managing supply chains with on-premise software is becoming impossible in the age of AI, where connectivity and access to data are everything.

–Riika Söderlund

Chief Operating Officer

Katana Cloud Inventory

Data that highlights the percentage of loads created or covered digitally today. Comparing this to where we’ll be in 2050 will illustrate the continued digitization of the industry.

–Jared Weisfeld

Chief Strategy Officer

RXO

I’d like to share some data on female representation in 2024. The supply chain sector does exceptionally well, with women representing 41% of the workforce and 26% of the C-suite (Gartner), but we’re still not seeing equal representation. I’d like our colleagues of the future to look back at these numbers and see today as the dawn of a successful journey to equality.

–Eva Skidmore

CMO

JAGGAER

A GPS tracking device to represent real-time visibility and a paper bill of lading, symbolizing digital transformation. These items would serve as benchmarks for how far we advance by 2050.

A GPS tracking device to represent real-time visibility and a paper bill of lading, symbolizing digital transformation. These items would serve as benchmarks for how far we advance by 2050.

–Vlad Kadurin

Chief Product and Operations Officer

Ship.Cars

In 2024, logistics was reactive and fragmented. In 2050, logistics transforms into a completely digital AI ecosystem. Decision intelligence dynamically guides autonomous vehicles and drones using real-time optimized routes for delivery, enabling end-to-end visibility. Smart warehouses are integrated with predictive demand systems that make decisions to carbon-optimize routes and slash emissions.

–Matthew Bunce

Decision Intelligence Engagement Principal

Aera Technology

Things of the past that demonstrate inefficiency and outdated practices.

1. Paper invoice – replaced by digital transactions.

2. Barcode scanner – obsolete with smart sensors.

3. Plastic pallet – replaced by biodegradable, reusable alternatives.

4. Plastic shrink wrap – eliminated by eco-friendly, reusable packaging.

–Stephen Dombroski

Director, Consumer Markets

QAD

An internal combustion engine as they power much of our supply chain, and it will be electric in the future; barcode scanners, which will be replaced by cameras and transform supply chain visibility; and a photo of the Panama Canal, which is drying up due to climate change.

–Sankalp Arora

CEO & Co-Founder

Gather AI

A traditional wood pallet. Though they were once a mainstay of the industry, the weight of wood-block pallets and their inability to be recycled has increased industry interest in the durability and sustainability benefits of plastic pallets.

–Drew Francis

Regional Manager

iGPS Logistics

I’d include things that shape supply chains today and will still matter in 2050: accurate forecasting tools, agile and smart supply chain strategies, and a focus on sustainability. Just like speed and service are timeless for retail, these are the essentials that keep supply chains efficient, flexible, and ready for whatever the future brings.

–Aki Elovehmas

Head of Product, Forecasting and Replenishment

RELEX Solutions

A screenshot of a logistics coordinator’s inbox, overflowing with “where’s my truck?” emails. Future generations will be amazed that putting a load on a truck meant losing sight of it until (hopefully) it arrived, and that we operated global supply chains with such limited real-time information, just as we now can’t imagine how businesses once managed without telephones.

A screenshot of a logistics coordinator’s inbox, overflowing with “where’s my truck?” emails. Future generations will be amazed that putting a load on a truck meant losing sight of it until (hopefully) it arrived, and that we operated global supply chains with such limited real-time information, just as we now can’t imagine how businesses once managed without telephones.

–Nick Rakovsky

Founder & CEO

DataDocks

A blueprint of today’s carbon-based transportation systems. By 2050, these will be replaced by greener, sustainable solutions like hyperloop or drone highways, dramatically reducing time, costs, and environmental impact. It will be fascinating to compare the carbon-based systems of yesteryear with those with zero carbon footprint and see how far we’ve come.

–Jennifer Chew

VP – Solutions and Consulting

Bristlecone

In our supply chain time capsule, we’d include AI-driven automation tools, blockchain technology for transparency, and a digital twin model to represent logistics operations. These innovations reflect how we’ve optimized the supply chain in 2025, paving the way for future advancements in efficiency, sustainability, and real-time decision-making.

–Kelly Sims

Owner, President, Chief Operating Officer

iJility, LLC

Copies of our current cargo theft laws and penalties, by state and federally, in the hopes that in 25 years when it is opened, we can see how far we have come.

Copies of our current cargo theft laws and penalties, by state and federally, in the hopes that in 25 years when it is opened, we can see how far we have come.

–Danny Ramon

Intelligence & Response Manager

Overhaul

I would put predictive analytics and address risk solutions into the time capsule to be opened in 2050, to remember the profound impact this technology had on the supply chain. Porch piracy and other delivery risk continue to be a top concern for consumers and merchants alike, and this technology allows them to mitigate risk and identify safe delivery options to improve customer experience.

–Dan Spitale

VP

UPS Capital

I would include frequently used paper documents including a handwritten BOL, trailer inspection form, tally sheet, sap order requests, pick up requests, inbound and outbound schedules, a handheld scanner, and a printed label for product. An FDA audit should be included as well as a master training record including forklift training and a safety vest, safety glasses, and helmet.

–Jackie Lauer

Warehouse Manager

TA Services

A delivery truck filled with a hefty amount of spreadsheets. Between drones and autonomous vehicles, it’s hard to imagine trucks would still be existing in their current form.

A delivery truck filled with a hefty amount of spreadsheets. Between drones and autonomous vehicles, it’s hard to imagine trucks would still be existing in their current form.

–Josh Dunham

CEO and Co-Founder

Reveel

A sustainability report to reflect the industry’s transition to more environmentally friendly practices, a 3D-printed vehicle part to represent manufacturing innovation, and a GPS tracking device to showcase our advancements in real-time tracking visibility. These items display progress made toward automation, transparency, and environmental responsibility by 2050.

–Mike Trudeau

Executive Vice President of Business Development

Montway Auto Transport

Our capsule would hold a stack of standard operating procedures and validation documents, as well as outdated logging and tracking hardware—symbols of the painstaking, manual processes once vital to ensure compliance and visibility across supply chains.

–Ilya Preston

CEO

PAXAFE