Healthcare Supply Chain: The Prescription for Success

The magic pill for today’s healthcare supply chain is composed of equal parts strategy, flexibility, and disruption mitigation—plus a healthy dose of technology.

The supply chain challenges involved in getting medical prescriptions and supplies to patients and care providers quickly and proficiently are plentiful—sometimes even daunting.

Issues can range from cold chain and environmental failures, to poor coordination and communication between supply chain points of contact, to risks incurred when medical supplies come from foreign countries with unpredictable political climates, to manufacturing breakdowns and the inability to meet demand.

As a result, the vital healthcare supply chain is under-performing in many ways. In a recent Deloitte survey of supply chain administrators, nurses, physicians, and service-line leaders, 24% of respondents “saw or heard about a recalled or expired product being used on a patient,” and 57% “recalled a time when a physician didn’t have the product required for a patient’s procedure.”

Why do healthcare supply chain challenges persist? The simple answer is that getting supplies to market safely and on time isn’t easy. Overcoming these logistics challenges doesn’t have a simple answer, but shippers, logistics providers, and technology companies are working together to help the critical healthcare supply chain advance and evolve.

“Many of the goods we ship come with a ticking clock toward expiration that is as short as 24 hours,” says Tim McClatchy, vice president of life sciences at Kenco Group. “The nature of the temperature-controlled pharmaceutical supply chain magnifies all the traditional challenges shippers face.”

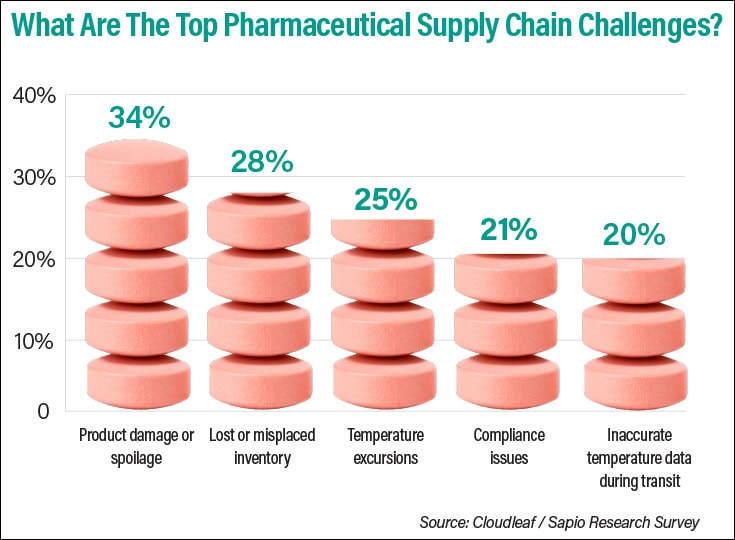

Failures in the pharmaceutical cold chain may cost companies as much as $1 billion in lost revenue annually as well as one million lost doses, according to a Cloudleaf and Sapio Research report.

In addition, medical and pharmaceutical supplies have gotten more costly. “Hospital supply expenses per patient increased 18.5% between 2019 and 2022, outpacing the rate of inflation by nearly 30%,” says John Carrico, vice president, product management for Epicor.

Other costly failures include microbial spoilage and compromised medical efficacy due to lapses in maintaining appropriate temperatures, humidity, moisture content, and packaging requirements in warehouses and transport vehicles. These failures also occur when medicines are not delivered on time.

“Products must be tracked to ensure authenticity and quality,” says Carrico. “Outbreaks, seasonal illnesses, or unexpected events can also have detrimental effects on healthcare supply chains.”

Optimizing Healthcare Logistics

Logistics and supply chain efficiency go a long way toward reducing spoilage and late deliveries. Due to the criticality of their goods, medical and pharmaceutical shippers and their supply chain partners must take extenuating factors into account to mitigate the risk of spoilage and damage.

When sending critical medical supplies from coast to coast, for instance, shippers must factor in the possibility of seasonal, weather-related delays along the route, such as tornadoes or hurricanes. “Even short delays caused by severe weather can lead to spoiled products,” McClatchy notes.

Breakdowns in the last mile can also sabotage delivery effectiveness. “One of the biggest challenges in managing last-mile logistics for the healthcare supply chain is ensuring compliance with regulations related to the handling and transportation of items such as specimens and healthcare records,” says Anar Mammadov, CEO of Senpex, a courier delivery service.

Coordinate and Integrate

The traditional supply chain challenges shippers face are magnified in the pharmaceutical supply chain because goods often have strict expiration dates and temperature restrictions. (PHOTO: Kenco)

Healthcare shippers and their logistics and technology providers are also focused on improving system integration and supply chain coordination. Though the healthcare sector is known for cutting-edge medical care, its back-end technologies and processes aren’t always as updated as they should be.

Many healthcare systems are not operating with integrated technology networks. Consequently, data coming from disparate systems isn’t always uniform, which can cause errors. That coveted “single version of the truth” is frequently lacking.

One example is a recent merger of two West Coast hospital networks that were challenged to find a solution for combining their electronic medical record systems. The workaround was for physicians and medical practitioners to toggle between two different systems, depending upon which hospital network a patient belonged to.

Many healthcare networks and pharmaceutical companies struggle with whether to update their own antiquated IT systems or invest in new third-party solutions.

“Having your own internal system may be appealing from a cost-savings perspective, but the time and resources needed to maintain and update an internal system—while keeping up with the pace of change in healthcare—quickly limits its usability as a long-term solution,” says Kristen Miles, vice president, healthcare product strategy at Oracle.

Spotlight on Risk

U.S. pharmaceutical shippers frequently source key components for medicines from China and other foreign countries, increasing the impact and risk of global supply chain disruptions.

Managing the risk of supply chain disruptions is a growing concern for the healthcare supply chain. In the United States, the industry relies heavily on components from China and other countries to a degree where disruptions in those global relationships put the supply chain at risk.

“China alone controls about 20% of the active pharmaceutical ingredients (APIs) necessary for our most critical medicines; it jumps to 45% when we consider key starting materials, the building blocks for APIs,” says Colonel Victor A. Suarez, USA (Ret.), lead vaccine program manager for the Moderna COVID-19 vaccine at Operation Warp Speed/BARDA in 2020-2021.

“Our over-reliance on China and other high-risk sources for vital components places us in a precarious position, subject to international politics and market manipulations,” he adds.

Suarez estimates that some 300 essential medicines were in short supply in the United States during 2023. “That shortage has real-world impacts, affecting everything from emergency services to cancer treatments,” he notes.

Moving Forward Through Technology

Strict handling and temperature-control procedures and frequently changing regulations challenge healthcare shippers. Partnering with experienced providers provides guidance.

As with most industries, the medical and pharma verticals are turning toward advanced technologies to help improve supply chain efficiency and effectiveness. From cloud computing to AI and robotics, among others, technology tools and solutions are rapidly changing the healthcare supply chain landscape.

Here’s a closer look at five technologies that healthcare shippers and logistics providers commonly implement to help manage their supply chains effectively.

1. Cloud-Based Supply Chain Networks

A centralized supply chain system, facilitated by the cloud, enables all parties involved in managing the supply chain to communicate, transact, and access the same set of data.

Cloud-based solutions can be particularly appealing to smaller companies for whom purchasing or licensing a complete supply chain solution is not financially viable. These companies can instead opt for a vendor-managed, cloud-based supply chain network that is set up on a subscription model.

“A cloud solution allows organizations to have the full suite of capabilities and functionality that they need, specifically designed for supply chain management and, with some vendors, specifically designed for the healthcare industry,” says Oracle’s Miles.

“Additionally, cloud solutions allow healthcare organizations to have the most innovative solutions at their fingertips and enable them to better keep up with continuously changing market dynamics,” she adds.

Gaining access to the latest supply chain technology without having to rely on in-house IT and systems is a major cost and time saver. Equally important is the ability of all supply chain participants to access and utilize a common, secure, and uniform data repository in the cloud.

2. Network Track-and-Trace Capabilities

Cloud-based track-and-trace networks allow healthcare professionals to monitor the flow of goods through the supply chain.

These networks enable authorized personnel at any point in the chain to view the location, delivery time, and other critical details of shipments.

Tracking also helps companies detect changes in shipments, such as failures in environmental controls that could compromise shipment quality.

Track-and-trace systems provide comprehensive visibility to all parties involved in logistics, warehousing, manufacturing, and receiving. IoT devices, RFID readers, barcode and QR code scanners, cameras, environmental and security sensors, and smartphones enhance these systems.

With these tools, healthcare supply chain participants can monitor shipment progress, ensure the safety of goods, and maintain the legal chain of custody.

In the event of an environmental or contamination alert, personnel can quickly identify the point of origin and take immediate action to quarantine the affected shipment.

3. Cargo Quality-Control Technology

Sensors and other IoT devices monitor and move healthcare supply chains forward and help ensure the quality of goods.

However, these advances also require employee training and compliance adherence as new regulations take effect.

Quality control technology has a human factor, too. “Teams must be trained to properly pick up, handle, and deliver supplies,” says Senpex’s Mammadov. “They also must be trained to ensure confidentiality and security for the items being transported.”

Healthcare companies must also stay abreast of new regulations impacting the supply chain. “We’re preparing for how enforcement of provisions within the Drug Supply Chain Security Act will impact our customers,” says McClatchy of Kenco.

“As drugs reach a pharmacy, the serialization data on the label must match with data on the drug stored within their systems,” he says. “This will help cut down on fake or incorrect drugs moving through the supply chain, but it also adds a new layer of monitoring that manufacturers need to consider as they design and affix labels.”

Compliance and security issues will continue to emerge, but technology providers in this space are helping shippers develop a solid base of implemented cargo quality-control technology that they can build upon.

4. Operational Automation

The supply chain is dealing with a challenging labor market. A nationwide shortage of an estimated 80,000-100,000 drivers persists, while 73% of warehouse operators are also having trouble finding labor. These broad challenges trickle down to the healthcare supply chain.

“Pharmaceutical manufacturers in particular must rethink how they position facilities to get life-saving products to customers while navigating a strained carrier marketplace,” says McClatchy.

Pharmaceutical and healthcare warehousers are rethinking locations, and more are moving facilities closer to their largest consumer markets. These warehouses also are adopting robotics, IoT, and workflow automation to handle routine tasks as a way to offset the labor crisis.

Warehouse robots can unload, store, pick, and fill orders, interfacing automatically with warehouse inventory systems so they can perform item counts and floor locations accurately and in real time.

Warehouse workflow automation also helps human workers reduce strain and cut down on injuries. Many warehouse workers are being retrained to leverage warehouse management systems through the use of RFID readers, tablets, smartphones, and headsets.

Workflow automation is also improving operations for healthcare companies.

“Healthcare organizations can effectively manage inventory and benefit from automated replenishment of critical supplies,” says Oracle’s Miles. “PAR [Periodic Automatic Replacement] management and mobile inventory capabilities help to ensure hospitals always have the supplies they need on hand, when they need them.

“These tools also allow teams to manage everything—inventory counting and reordering, stocking inquiries, and sub-inventory transfers—on the go,” she adds.

5. AI and Risk Management

Today, supply chain risk management is more important than ever as disruptive events have almost become a supply chain fact of life.

Any type of disruptive event—from a pandemic to a bridge collapse to severe weather—can jeopardize the delivery of supplies such as pharmaceuticals. As a result, healthcare companies are increasingly turning to predictive AI software to assess their greatest supply chain threats.

“These predictive forecasting tools can help identify and prepare for demand, optimal inventory levels and costs, and aid in reducing any disruption a healthcare organization may encounter,” says Epicor’s Carrico.

Building on the Foundation

Managing healthcare supply chains can be a complex and unpredictable task, necessitating new tools, solutions, and methodologies for effective management. Technology also offers a way forward.

The foundation is a best-in-class, cloud-based supply chain system that ensures all participants use the same high-quality data. Next, automating work processes and manual operations reduces errors through consistent, repeatable tasks.

IoT devices, robotics, and advancements in QR codes and RFID readers further enhance efficiency and accuracy.

Ensuring the integrity and authenticity of pharmaceutical and medical supplies requires unbroken chains of custody, planned responses to supply chain disruptions, and continuous tracking and tracing of shipments. Advanced logistics networks and warehouse systems can provide these capabilities.

Healthcare supply chain managers must now decide which technological advancements to adopt to achieve the next level of supply chain evolution.

A New Platform as the Remedy

EmblemHealth is one of the nation’s largest nonprofit health insurers. It has 3.2 million members and an 80-year legacy of serving New York’s communities.

When EmblemHealth acquired a hospital network and a for-profit health maintenance organization recently, it inherited a patchwork of systems that ran on different platforms. The data between systems wasn’t uniform and information was streaming in from multiple places and sources.

As a result, employees were unable to work together on a single platform with a single source of data. They managed procurement and invoicing in one system while handling accounting and budgeting in another. Several systems were antiquated and in need of upgrades and employees could not obtain a 360-degree view of the enterprise through reports or analytics.

The IT was clearly unsustainable, so EmblemHealth decided to move its supply chain, finance, and HR systems to a cloud-based solution.

The company engaged Cognizant as project consultant and selected a suite of cloud-based systems from Oracle, consisting of SCM (supply chain management), ERP (enterprise resource planning), HCM (human capital management), and SPM (sequel plan management). The platform migration took 11 months, but EmblemHealth soon reaped the benefits.

“We cut processing times from three days to less than three hours,” says Valentino Daloisio, vice president of finance for EmblemHealth. All employees can now utilize the same information and each of the systems are automated, standardized, and streamlined.

EmblemHealth is still in the early stages of its system/operational transformation, but it expects the migration to cloud-based systems to save as much as $700,000 annually, in addition to IT savings of some 30% over the next five years.