Fixing Automobile Supply Chain Inefficiencies with Real-Time Location Intelligence

The automotive supply chain stands as one of the most complex networks of interdependencies in the world. Each segment of this supply chain is vital, from the original equipment manufacturers to the transporters.

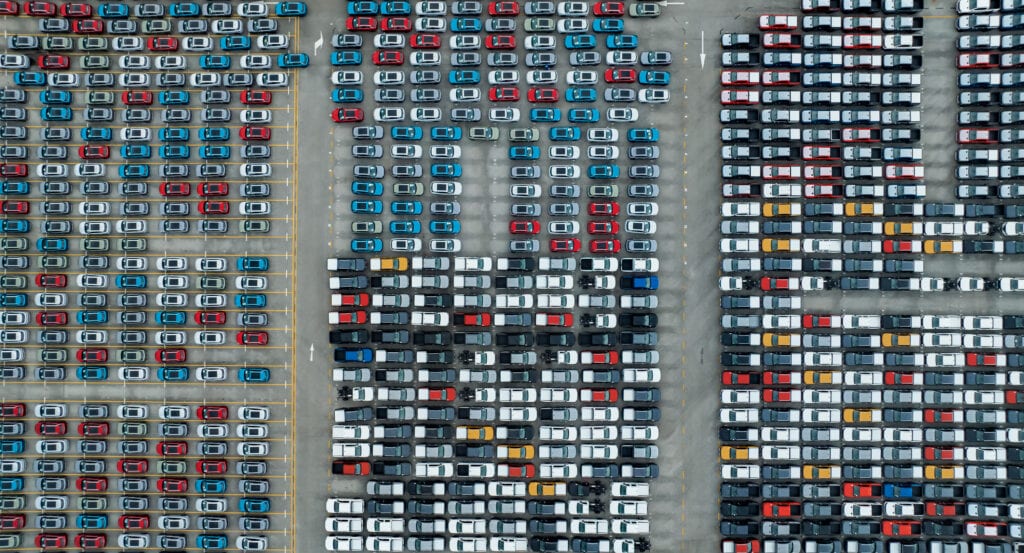

One particularly important link in this chain is the Finished Vehicle Logistics (FVL) yard, which is responsible for storing and preparing vehicles for their inevitable transportation to dealerships. These yards are massive, spanning hundreds of acres and containing thousands of vehicles at various stages of readiness.

Unfortunately, FVL yards run into many challenges, with the smallest misstep (one vehicle being out of place) being enough to trigger delays that drive up costs.

The Major Challenges of Finished Vehicle Logistics

Vehicles need to be relocated multiple times within an FVL yard. During these movements, there is a risk the vehicles could get misplaced or damaged. A driver behind schedule might stash a car hastily and in the wrong place. These misplaced vehicles can have a snowball effect on the larger supply chain. Long wait times lead to short-shipped loads and detention charges, including frustrated dealerships.

Another challenge is what is known as “lot rot” or the damages and issues such as scratches, component degradation, and tire damage that accumulate during prolonged storage. Lot rot is particularly prevalent today, with new vehicle inventory increasing, hitting 2.93 million in the current month, while vehicle movement sits at 1.13 million. If these issues go unresolved, there can be compensation fees for undelivered vehicles and further delays to the supply chain.

Likewise, working conditions, in the form of inclement weather, can impede FVL yards’ ability to have vehicles ready for pickup. Rain, fog, or snow may prevent drivers from locating vehicles across the massive expanse of a yard or driving it without causing damage. The pressure to stay on schedule also results in high turnover, creating labor shortages.

Addressing These Challenges with Real-Time Location Intelligence

The commonality between these challenges is a lack of visibility into vehicle location and movements, which prevents workers from finding, transporting, and servicing vehicles promptly. As such, innovative FVL yards are implementing real-time location intelligence solutions that incorporate technologies like GPS-enabled tags, Radio Frequency Identification (RFID), and Bluetooth to track tagged vehicles and gain an understanding of their real-time movements.

With real-time location intelligence, FVL operators are instantly notified of a vehicle’s new location every time it moves, eliminating the need for manual reporting and yard checks, which helps boost overall productivity. Moreover, the greater visibility possible through real-time location intelligence means no tagged vehicle will ever be outside the operator’s knowledge, protecting FVL yards from delays, fees, and upset partners while ensuring an unbroken consistency across the automotive supply chain.

Perhaps an even more powerful benefit of real-time location intelligence comes from analyzing the wealth of data collected from these thousands of vehicle movements by every driver employed in the yard. Some real-time location intelligence solutions include tools that allow FVL managers to investigate this data and extract valuable and actionable insights.

Some notable key performance indicators (KPIs) include average move time per vehicle per driver, wait time between moves, damage reporting by vehicle by driver, and driver utilization (including time for breaks). These KPIs enable FVL managers to readily identify inefficiencies and bottlenecks and implement suitable changes to increase throughput and reduce wasteful moves.

Gaining a Competitive Edge

Real-time location intelligence solutions are the key to solving supply chain inefficiencies at the yard level. Nevertheless, success doesn’t just mean fixing issues but going beyond. To that end, FVL managers should seek to differentiate themselves by utilizing best-in-breed solutions, especially those that use advanced technologies like artificial intelligence and machine learning.

Furthermore, FVL managers should prioritize solution providers with proven expertise in overcoming connectivity congestion and coverage problems. Such capabilities will empower FVLs to gain an edge over competitors using the same technology.