Caldwell Hospital Gets a Lean Bill of Health

A North Carolina hospital improves patient care by prescribing a lean and healthy supply chain.

It took some time for Caldwell Memorial Hospital to discover that the muscularity of its supply chain had atrophied because excess waste was impeding its commitment to providing quality service to its patients. It was an epiphany for the small, 110-bed hospital, located in rural Lenoir, N.C.

A lack of effective inventory control and oversight, multiple stock locations, and an overly complicated sourcing process caused the hospital to take a long, hard look at how to move hundreds of critical items—such as disposable syringes and latex gloves—more effectively and economically from the vendor to the patient’s bedside precisely when they’re needed.

"We knew we had to change the way we did things in order to bring better value to our patients," says Heather Foss, Caldwell’s director of quality, risk management, and performance improvement. The hospital realized that it needed to trim the fat and go lean.

In 2008, the North Carolina Healthcare Initiative Collaborative, under the auspices of the University of North Carolina’s Healthcare Network, received a grant from the Duke Endowment to fund small rural hospitals in North Carolina in an effort to migrate their operations to a lean management protocol. The move was seen as an all-out campaign to cut the excess from day-to-day clinical functions that would reduce costs and maximize the efficiency of its 900-plus employees and more than 150 physicians.

A coalition of five rural hospitals, including Caldwell Memorial—dubbed the Carolinas Lean Healthcare Collaborative (CLHC)—was formed to oversee the transition process. The decision was made to partner with Simpler Consulting, a Truven Health Analytics/IBM Watson company specializing in helping healthcare facilities infuse the lean management process into their operations.

Over the next six years, Simpler carried out assessments of nine value streams at Caldwell Memorial, including in-patient care, surgery, revenue cycles, emergency room operations, and diagnostic imaging. In November 2014, the company turned its spotlight on Caldwell’s supply chain and began a highly detailed assessment of its inventory visibility, spend, and operations—the first step in designing and implementing a course of action.

Linking Vendor to Patient

"We took a hard look at the warehouse operations and the process linking the vendor with the patient’s bedside," says James Spann, Simpler’s global practice leader for supply chain management and logistics. "The existing process focused on the transactional effort such as getting requisitions in, working with vendors, group purchasing organization, getting products into the system, distributing them, and making sure the vendor got paid."

The decision was made to implement the latest technologies in certain specific areas including supplier contracting, management, and performance; pricing and value analysis; the standardization of products; consolidation; vendor relationships; inventory control; job functions; productivity; and replenishment systems.

"With Caldwell, we decided to focus on inventory, productivity, and technology," says Spann. "We saw they needed to zero in on improving inventory visibility in tracking and monitoring product to make sure they have the right product available when they need it.

"Along with that is distributing product from dock to bedside," he adds.

A 15-month program was put in place that broke down Caldwell’s supply chain operations into five "support flow cells": procurement/sourcing; receiving/sorting; inventory optimization; distribution flow; and payment.

Inventory optimization and distribution flow were identified as the two areas most in need of rehabilitation.

The hospital’s operating room was found to be functioning with cumbersome multiple inventory ordering processes that resulted in serious limitations on the quantity of critical supplies and the frequency with which they could be reordered.

The first step called for the installation of a point-of-use stock location system that helped Caldwell gain what Spann calls "tactical control" over its supply chain by identifying specific inventory costs that could be reduced.

As a result, the hospital’s inventory was brought under control by lowering expenses, increasing inventory visibility, eliminating stock outages, and maximizing utilization—in short, getting everything right: place, quantity, and price.

The results have been impressive, says Foss, with a total reduction of 3,746 square feet of supplies and a cut in the number of SKUs at its two wings by an average of 20.5 percent from 843 to 665.

In addition, the seemingly chronic product return issues that revolve around not knowing what is and isn’t on the shelves was replaced with BlueBin technology that simplifies the distribution process by using visual "triggers" to deliver the right supplies to the right place at the right cost.

"We no longer have to stock our own med rooms as that’s now managed by the new lean system," says Foss. "There’s more space, better flow, and we’re no longer in each other’s way. We can spend less time searching for products and more time on value-added work."

Let’s Get Visible

The task of infusing complete visibility of the entire supply chain process was accomplished with the help of a partner tech firm, which oversaw the installation of new software to standardize operations procedures, including real-time visual management, into Caldwell’s supply chain operations. The inventory management software that was installed "sits on top of the supply chain and offers complete visibility to show vital statistics and identify specific issues that need to be addressed," says Spann.

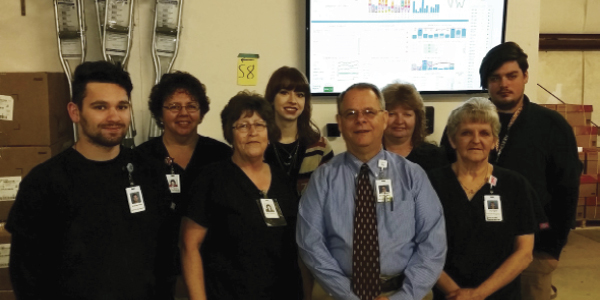

With the system fully implemented, Caldwell now monitors its supply chain on-site—a highly successful technique that Caldwell found "directly and effectively involves the people who do the work, where they work," says Foss.

Such a setup gives staffers the wherewithal "to know what’s going on in the entire system," says Spann. The staffers monitor the supply chain that is installed with the client for six months or one year to help implement the system. "If things go off the rails, they jump in and fix the problem at the point of entry, like a plant floor supervisor or manager who makes sure that the operation is running effectively all the time," he adds.

As for Caldwell, "We installed key dashboards in ‘mission control rooms’ that display conditions along every link of the supply chain on 50-inch computer monitors in real time," says Spann. "We built, designed, and implemented technology-based solutions, and trained their people how to best utilize them because they are going to have to take it over."

The process to inject lean into Caldwell Memorial’s operations was relatively easy due to the engagement of hospital CEO Laura Easton.

Lean, says Spann, is a concept that results in continuous improvement, but one that will work only if senior management is involved from start to finish. Easton’s mission control is the hospital’s executive conference room, where she meets with her leadership team daily on key issues and what’s being done to improve operations.

According to Foss, the overall results of implementing a lean supply chain strategy have been a significant reduction in employee frustration and improved product availability. In addition, end users have been removed from the supply management process; excess and obsolete supplies have been eliminated; and order placement is virtually error-proof, while products standards have been set and maintained and cost has been significantly decreased.

The Bottom Line

In bottom-line terms, "The return on investment (ROI) is monitored for every value stream," says Foss. "Now we’re able to keep track of both direct and indirect value of return," she says, pointing to a reduction in supply spend of $1.4 million, a true ROI of slightly more than $2 million, or 3.4:1 achieved, generated from January 2015 to May 2016 with supply chain spend as a percentage of net revenue cut from 22 percent to 19 percent.

Lean assessment identified a potential reduction of $421,000 in distribution costs, as well as $366,000 from a reduction in the time Caldwell’s clinicians spent managing the hospital’s supply chain.

"When we started assessing Caldwell’s supply chain, we stationed an augmented team to get the operation up and running," says Spann. "After 15 months, we started to wean off. We finished implementing the lean concept in April 2016 and performed a refresh audit of their inventory control component in August and September. We recommended and are conducting some retraining. But now they’re self-contained and running on their own, and we still work with them in an executive coaching capacity and advisory role."

"Over time, Caldwell Memorial has been able to groom and grow internally, so Simpler currently fills a critical advisory and executive coaching role," says Foss. "We’re doing things smarter and what’s most important is that our patients are receiving better care because of it."