Going in Reverse in the Circular Economy

While 70% of supply chain leaders plan to invest in the circular economy in 2020-2021, only 12% have aligned their digital and circular economy strategies so far, according to a recent survey by Gartner. About 27% of respondents currently use digital technologies to improve reverse logistics, and 39% plan to do so in the next two years.

Reclaiming materials at the end of life requires reverse logistics for pickup and return to the organization or a third party. Reverse logistics will gain the most attention, says Gartner, indicating that companies are looking at how to take back products for reuse, refurbishment, or recycling—an important step toward a circular economy.

This business model involves complex interdependencies and feedback loops, Gartner notes, starting with an ideal design and planning for end-of-life and raw material reuse. Digital technology can enable visibility and improve decision-making when it comes to raw materials and services.

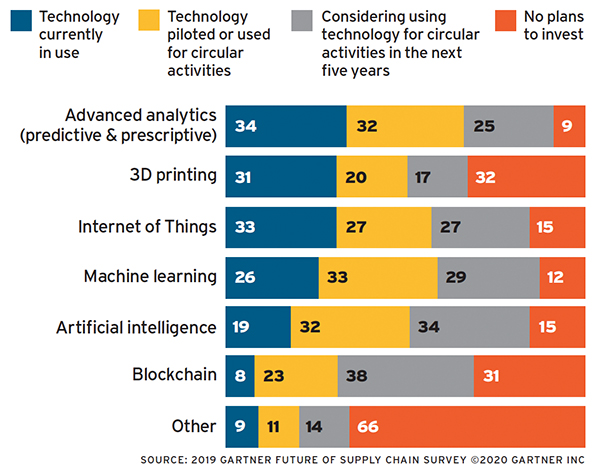

Organizations currently focus on the following four technologies to advance their circular economy activities (see chart):

- Advanced analytics

- 3D printing

- Internet of Things

- Machine learning

The top four areas of the supply chain in which these digital technologies are applied are:

- Delivery (46%)

- Customer engagement (45%)

- Manufacturing and remanufacturing (43%)

- Planning (43%)